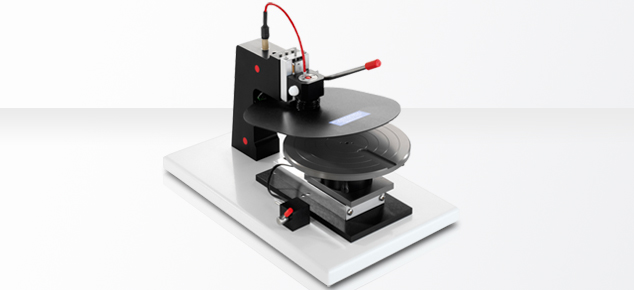

The Multiposition Wafer Probe combined with the ResTest Test Unit provides a high quality, easy to use system for measuring the sheet resistance and/or volume resistivity of wafers up to 200mm (8″) in diameter.

About the Jandel ResTest Four Point Probe

- Constant current source and meter for use in making the four point probe measurement.

- Measurement range: 10 milliohms-ohms-per-square to 10^6 ohms-per-square

- Displays either sheet resistance or volume resistivity.

- Save data using:

- PC connection

- Up to 99 measurements can be stored internally, or

- USB memory stick

- Accommodates either linear or square array probes and 6 choices of probe tip spacings

- Supports four measurements types:

- Sheet Resistance – Primary measurement value is display in Ohms/Square

- Wafer Resistivity – Primary measurement value is display in Ohms/Cm

- Volume Resistivity – Primary measurement value is display in Ohms/Cm

- Ohms Resistance – Primary measurement value is display in Ohm

- Three available current ranges:

- 0.5mA to 10mA

- 10uA to 100uA

- 1uA to 10uA

- Includes PC interface software

- Interfaces with Jandel four point probing units

Multiposition Wafer Probe

The Multiposition Wafer Probe has the ability to probe 1, 5, 9, or somewhat more positions on multiple wafers with 1mm positioning repeatability from wafer to wafer. It is not motorized, but requires that the user moves the wafer stage by hand. It is available with either a 6″ (150mm) wafer chuck or an 8″ (200mm) wafer chuck.

The price is the same for either unit, however, the MWP-6 would be preferable for use with wafers that are 6″ in diameter or smaller due to the increased ease of centering the wafer on the wafer chuck. Annular rings (not vacuum rings) allow wafers to be centered more easily. To aid in centering smaller wafers, the 6″ Multiposition Wafer Probe has circular patterns on the wafer chuck with diameters of 25mm, 50mm, 75mm, 100mm, and 125mm.

The 8″ system has circles at 125mm and 150mm. The Multiposition Wafer Probe can be connected to a vacuum source for wafer hold-down. The instrument comprises a white powder-paint coated metal base carrying a Delrin column supporting the vertical slide, operating lever shaft, and micro-switch. The vertical slide carries the probe head, secured by a clamp screw. The probe head is positioned so that the micro-switch does not pass current until the probes have made contact, lost motion ensures that the current is switched off before the probes are raised. The wafer table slides towards the operator to enable the wafer to be centrally positioned, after which the vacuum control valve can be operated to secure it in position.

When the table is pushed to the limit of its travel, a measurement can be made at it’s center. Four radial positions at right-angles are denoted by a spring-loaded index ball incorporated in the rotary table. The radial distance of measurement is denoted by a similar arrangement on the linear slide index plate. Unwanted settings can be blocked off by easily removed screws. So that, for example, one could choose to measure at the center and four points at 50mm radius. A grounded metal shield screens the wafer from light and electrical noise during measurement. It is arranged that the shield rises when the probe head is fully lifted to permit loading.

The system incorporates the Jandel Cylindrical probe head which is built to high standards of quality and accuracy.

Multiposition Wafer Probe Specifications:

Wafer Chuck – Hard anodized aluminum alloy with vacuum hold, centering grooves, and tweezer notch for: 6″ model – 3″, 4″, 5″ and 6″ wafers, 8″ model – 5″, 6″, and 8″ nominal diameters.

- 6″ Model Preset Measurement Positions: Center and four radii at right angles 15, 20, 25, 35, 50, and 60mm

- 8″ Model Preset Measurement Positions: Center and four radii at right angles 32, 38, 50, 57, 68, and 94mm

- Services: Vacuum line or pump required

- Dimensions: 355 x 215 x 195mm high

- Net weight: 6″ model – 3.5kg, 8″ model – 4.0kg

| Sampling Plan C, ASTM F-81-89, using MPW-8″ | ||

| Wafer | 1/2R | 6mm from edge |

| 5″ | 32mm | 57mm |

| 6″ | 38mm | 68mm |

| 8″ | 50mm | 94mm |

ResTest Four Point Probe Measurement Unit

The ResTest is a combined constant current source and digital voltmeter, which has been designed specifically for use with a four point probe to produce resistivity and sheet resistance measurements. The unit supplies a constant current and can display resultant voltage sheet resistance and volume resistivity.

The ResTest has a large color display and it can read-out in either sheet resistance in the range from 10 milliohms-per-square up to 106 (1 million) ohms-per-square. The range is not as great as the RM3000, however, it is faster and has a larger color display.

Downloads

We Recommend

If you do not require as great a measurement range as the ResTest Test Unit provides, you might be interested in the: Multiposition Wafer Probe combined with the HM21 Hand Held Meter.

The Multiposition Wafer Probe with the RM3000 Test Unit features high accuracy, an excellent range, and many features which simplify the four point probing measurement: Multiposition Wafer Probe combined with the RM3000 Test Unit.

Four-Point-Probes is a division of Bridge Technology. To request further information please call Bridge Technology at (480) 219-9007 or send e-mail to Joshua Bridge at: sales@bridgetec.com