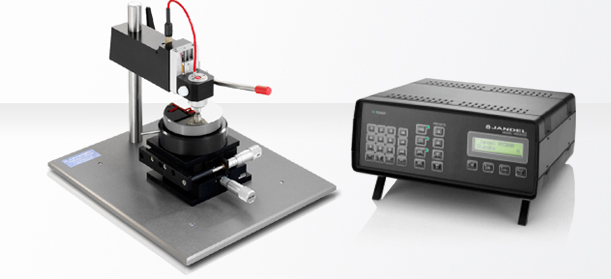

The Multi Height Microposition Probe combined with the RM3000+ Test Unit is Jandel’s most versatile four point probing system. It includes a fine X-Y stage for positioning small samples under the four point probe tips. The X-Y stage can be easily removed for measuring large samples such as substrates up to 10″ x 10″, or tall materials up to 6″ tall.

The RM3000+ Test Unit is Jandel’s superior measurement electronics which was designed specifically for the four point probe measurement. The RM3000+ has a measurement range from 1 milliohm-per-square up to 5 x 10^8 ohms-per-square with 0.5% accuracy. The volume resistivity measurement range is from 10^-3 to 10^6 ohms-cm.

Multi Height Microposition Probe

The Multi Height Microposition Probe comprises a hard anodised aluminium base 25cm wide, 29cm deep and 0.8cm thick. A 19mm diameter stainless steel column 20cm high screwed to the base supports the probe head raising and lowering mechanism incorporating the vertical slide, operating lever shaft, and micro-switch.

The vertical slide carries the probe-head, secured by a clamp screw. The probe-head is positioned so that the micro-switch does not pass current until the probes have made contact; lost motion ensures that the current is switched off before the probes are raised. The probe arm can be easily positioned on the vertical shaft to various heights to allow probing onto either flat materials or large or thick materials. For example, a shallow dish containing LN2 could be placed on the base plate and the arm could be positioned to allow the probe to be lowered onto a sample submerged in liquid nitrogen. With the X-Y stage removed, materials up to 10″ x 10″ x 6″ tall can be positioned under the probe arm. If necessary, a taller vertical post can be supplied for use in measuring taller items.

The Multi Height Microposition Probe includes a removable X-Y stage which can be bolted to the base plate to aid in positioning the materials accurately when probing onto small samples.

Features of the Removeable X-Y Stage:

|

|

The RM3000+ Test Unit is a specialty electronics instrument designed specifically for the four point probe measurement. It features high accuracy, an excellent range, and many features which simplify the four point probing measurement. The following are features of the RM3000+ Test Unit:

- The sheet resistance range of the RM3000+ Test Unit is from 1 milliohm-per-square (10^-3) to 10^8 ohms-per-square with 0.3% accuracy. The volume resistivity range is from 1 milliohm-cm (10^-3) up to 10^6 ohms-cm, however, that resistivity range refers to measuring a bulk material directly as opposed to measuring a thin film and converting to volume resistivity using the software. For example, a thin layer of copper (1.68 x 10^-6 ohm-cm) up to about 16 microns thick can be measured. The RM3000+ can determine the volume resistivity value if one enters the film thickness.

- The RM3000+ includes PC control software which can be used for measurement logging (storing data in CSV format) and can save measured values as sheet resistance or volume resistivity.

- The RM3000+ display reads-out the input current as well as either ohms-per-square (sheet resistance), ohms-cm (volume resistivity), or millivolts, without requiring the use of the included PC software. The volume resistivity readout requires entering thickness for a wafer or thin film, or tip spacing if measuring a bulk sample.

- The RM3000+ has onboard non-volatile memory so that up to 50 measurements can be stored internally and then downloaded and saved all at one time using the software. Alternately, each measurement can be saved to a PC as it is made using the included software.

- The RM3000+ has an auto-range button that can be used to automatically determine the optimum input current for a given material without using the trial and error method.

- The RM3000+ has forward (FWD) and reverse (REV) buttons to reverse the direction of current flow. A common way to determine if a measurement is valid is to reverse the direction of current flow and then check to see if the forward and reverse voltage readings correlate well, i.e., the values should be similar, but with the reverse current voltage being a negative value.

- The RM3000+ allows the input of a correction factor for samples that need to be corrected for size.

- The RM3000+ has a date and time stamp feature

Superior Current Source

- 10nA to 100mA (99.999mA) current source selectable in steps to 3 decimal place resolution

- Current set numeric keypad

- 4 default preset current programs (user programmable)

Superior Inbuilt DVM

- Input Impedance 1,000,000,000,000 ohms

- Input Bias current 4pA

- DVM 1300mV range and 130mV range

- 130mV accuracy

- 0.2% +/- 5uV resolution (10uV or 1uV) range

- 1300mV accuracy 0.2%+/-100uV resolution

- 100uV Ohms/Square

- Rapid Zeroing null function for DVM

Features

- 28 Key high quality Keypad

- 16×2 line LCD Display for simultaneous indication of Set Current and either Ohms/Sq or mV

- Auto-Ranging capability to determine the optimum input current based upon the material being measured.

- Intuitive operation

- Microprocessor controlled

- Reduced Footprint

- Robust Attractive ABS Case

- Accurately measures down to 10’s of milliohms/square without external meter

- 4mm socket facility to connect an external meter

- RS232/USB connectivity for control and for collecting data in CSV format

- Automatic compliance voltage limit protects your sample which reduces maximum voltage as higher currents are set 5-40V

- Warning messages when compliance limit is reached, or DVM input exceeded

- Self test facility

- Flash upgradeable software

- CE Marked

- AD/DA converters and amplifi

Cylindrical Probe Head

The Cylindrical probe head, one of which is included with the Multi Height Microposition Probe, can withstand temperatures from 77K up to 120C in it’s standard configuration. A modification to the Cylindrical probe will allow it to withstand temperatures from 77K up to 200C (in an oven). The Multi Height Microposition Probe is conservatively limited to 80C, however, temperatures up to 300C using a hot plate are okay if certain precautions are taken. The Cylindrical probe head is built to high standards of quality and accuracy. A brochure regarding the Cylindrical probe can be found here:

https://four-point-probes.com/jandelcylindrical.pdf

An application note with information regarding the constructions and specifications of the Jandel Cylindrical probe can be seen here: https://four-point-probes.com/cylindrical_app_notes.pdf

Downloads

Four-Point-Probes is a division of Bridge Technology. To request further information please call Bridge Technology at (480) 219-9007 or send e-mail to Joshua Bridge at: sales@bridgetec.com